More and more lignite and coal gangue produced by coal mines are crushed and sold to coal chemical enterprises for further processing.

In the coal industry, the requirements for the particle size of the finished product are extremely strict. Generally, the particle sizes of the finished products are between 25 and 70 mm. If it is too large, the furnace will be blocked and further coal processing can't be performed.

Toothed roll crusher is the mature coal crushing equipment applied in the current coal industry, which satisfies all the demands of customers by its advantages of large capacity and low over-crushing rate.

Coal crushing--toothed roll crushing

Based on the original toothed roll crushers, HXJQ Mining Machinery has optimized the structure and materials of rollers according to the customers' requirements, so that to adapt the nature of hard gangue and special working conditions and ensure the normal production of coal enterprises.

Structure improvements

Traditional toothed roll crusher

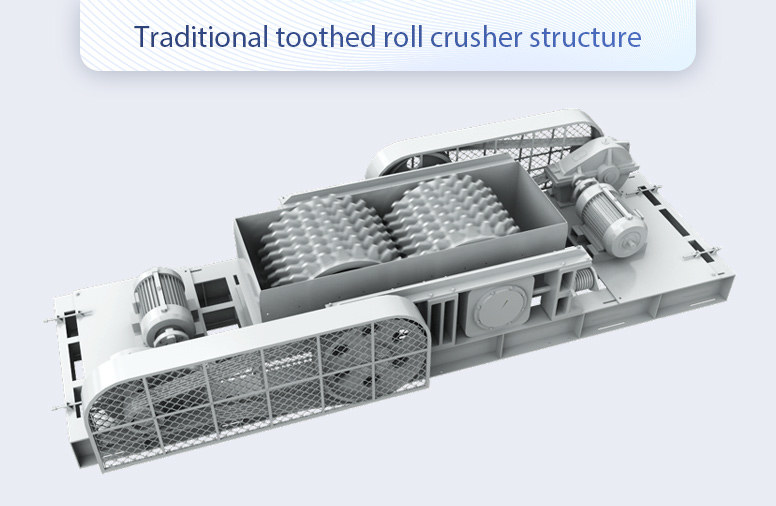

Traditional toothed roll crusher is usually driven by double-motors. Two sets of motors, couplers and reducers are adopted to drive the independent rollers so that the rollers have the power to crush large coal materials.

Traditional toothed roll crusher structure

The coupler is applied between reducer and rolls to transfer torque. And the toothed rollers and drive system are connected with the machine frame respectively to eliminate the vibrating of toothed roll crusher.

In general, the traditional toothed roller crusher with 70mm discharging size adopts the ring structure or roller structure.

Traditional toothed roll crusher with ring structure has the advantages of stable and reliable performance, and the disadvantages of low wear resistance and hard to replace. Once the traditional toothed roll crusher is damaged, it must be returned to the factory for overhaul.

The traditional rollers are connected by the bolts and tooth-holders, which offers small bearing capacity. Therefore, the traditional toothed roll crushers are mainly applied in the clean-coal crushing process, because the raw coal will cause damage to roll crusher teeth.

New-type toothed roll crusher

The tooth's position and the connecting structure between roll and tooth-holders of new-type toothed roll crusher have been improved.

In terms of tooth position, the roll crusher teeth are set in the peripheral direction, adopting the setting form of large tooth alternating with a small one. Under the premise of normal discharging size, the crushing force of roller can be improved efficiently, so that to increase the capacity, wear-resistance and service life.

Improvements of toothed roll crusher

Since the raw coal has the feature of large particles, HXJQ engineer has optimized and designed the connecting structure of roller crushers reasonably.

As the picture shows, the new-type tooth-holder adopts the form of regular octagon. The toothed rollers and toothed holders are connected by the flat kay and socket head cap screws (the traditional ones are connected by bolts).

The contacted areas between tooth and toothed holders are processed and improved completely, and torque is transferred by flat key so that can prevent the socket head cap screws from the shearing force of coal materials. And the screws can be firmer and more reliable.

Meanwhile, the fastening bolt and the toothed roller holder are connected by the screw fastening blocks, which makes that the joint strength is ensured, and the interchangeability and the replaceability are also reliable.

Materials improvements

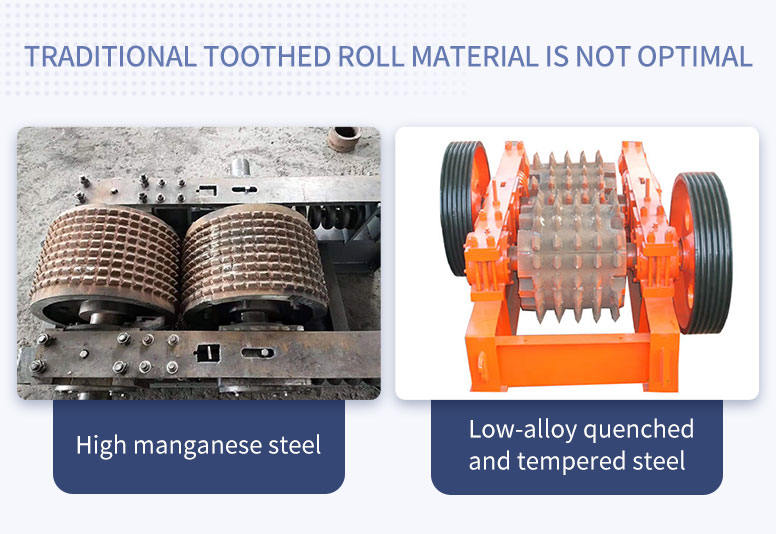

The teeth are the main wearing parts of the toothed roll crusher, so it is very necessary to choose a suitable material. Therefore, it is required that the material should have enough hardness, toughness, impact resistance and wear resistance. Also, the following machinability and weldability should be considered.

Traditional teeth' materials

At present, the most common wear-resisting materials are high manganese steel and low-alloy quenched and tempered steel.

Traditional teeth' materials

High manganese steel

high manganese steel is one of the most common wear-resisting materials and after the heating process, the high manganese steel has great toughness and low hardness.

When parts of high manganese steel are impacted repeatedly, the surface of parts gets changed, and the hardness increases rapidly, which can reach up to HRC54. It will improve the wear resistance significantly, but the inside of parts keeps flexibly. These are the main features of high manganese steel.

However, the toothed roll crushers crush coal materials by shearing and stretching, along with less impacting and squeezing, which makes high manganese steel can't play its advantages to enhance the hardness and strength. Therefore, high manganese steel is not suitable for making teeth.

Low-alloy quenched and tempered steel

To better improve the wear-resisting performance of teeth, traditional toothed roll crusher always adopts the low-alloy quenched and tempered steel as the material to make tooth of roll crushers. In general, 40 Cr is used to process the tooth. After processing, the compressive strength and the service life of tooth are improved.

However, since there are only a few millimeters thick wear-resisting layer in the surface of the tooth, it is required to be overlaid frequently in the process of use, which brings a large workload to workers.

At present, this kind of toothed roll crusher is mainly used to crush soft materials such as clean coal, but not for crushing raw coal.

New-type tooth material

Medium carbon bainitic steels

New teeth's material

The teeth of the new toothed roll crusher adopt the integral casting molding process, optimizes the proportion of the main elements such as C, Cr, Mn, Mo, Si, Ni. The medium carbon bainitic steel is selected finally to be the material of toothed roll.

The medium carbon bainitic steel has good hardenability. After quenching and tempering heat treatment, bainite with high hardness and wear resistance is processed. It has an excellent comprehensive performance of HRC50 hardness and compressive strength of 1500 MPa.

In addition, the material of the entire toothed roller structure, including the toothed roller, the toothed roller holder and the threaded fastening block, is reasonably matched, so that the strength and hardness of each component are more balanced and reasonable.

Application improvements

The raw coal mining in an open-pit coal mine located in East Kaliman Island, Indonesia, uses a semi-continuous mining process of a single-deck truck.

The raw coal of large particle size and high hardness contains a large amount of vermiculite.

The raw coal is first crushed to below 300mm by the jaw crusher, and then crushed to below 70mm by a toothed roller crusher, and then transported to the coal storage bin by the belt conveyor. After screening, the final product of 25~70mm is sold to the chemical company.

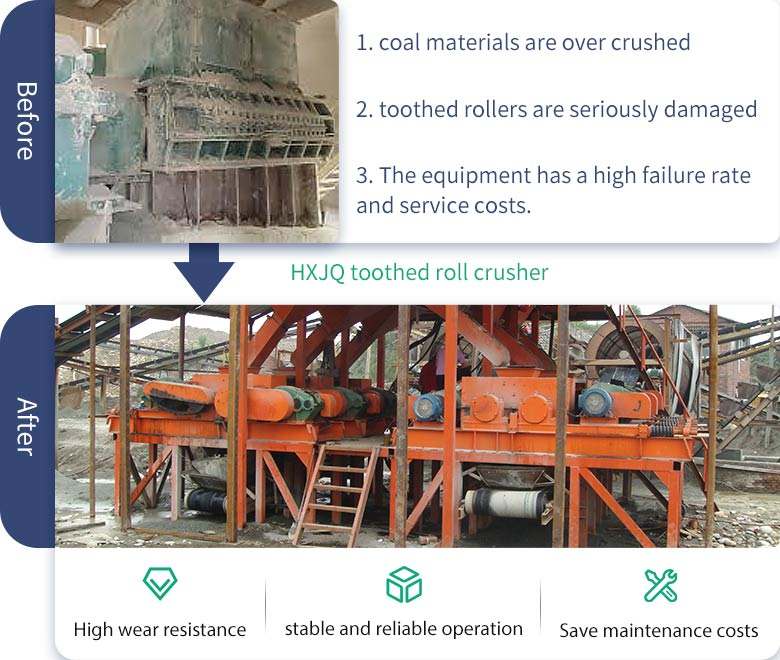

The original toothed roll crusher has the following faults after long-term operation:

A large amount of coal materials is over crushed, which seriously reducing the economic benefit of the enterprise.

The toothed rollers are seriously damaged, which will cost a lot on its maintenance.

The equipment has a high failure rate and high maintenance costs.

The customer said it requires technical improvement urgently in their worksite urgently to reduce the operating cost of the enterprise and the labor intensity of the workers and to ensure the normal operation of the production system.

After many investigations, the HXJQ Mining Machinery engineers finally recommended a new type of toothed roller crusher to replace the original one.

Worksite comparisons of toothed roll crusher

Since the new toothed roller crusher was put into use, the equipment has been running stably, the discharge size of the products is significantly improved, the over-crushing rate reduces, and the block-forming rate is highly increased (see the following table).

Discharging size: Traditional VS New

| Discharging size | Qualified products rate of traditional toothed roller crusher% | Qualified products rate of new-type toothed roller crusher% |

| Below 25mm | 56.3 | 45.7 |

| 25mm-70mm | 26.3 | 44.5 |

| Above 70mm | 17.4 | 9.8 |

Slide to the right>>

It can be seen from the above table that the difference between the qualified products before and after the replacement is 18.2%, which greatly improves the output of qualified products and creates great economic benefits for the enterprise.

In addition, the new toothed roller crusher has high wear resistance, and the fastening bolt is not easy to loosen, which reduces a large amount of maintenance time, the labor intensity of workers, and the maintenance cost of the coal crushing process.

Conclusion

With the transformation and upgrading of the coal industry, it is an inevitable trend to vigorously develop coal chemical industry. The coal chemical industry has strict requirements on the particle size of coal, which puts higher requirements on the crushing equipment.

The new toothed roller crusher can optimize the crushing operation of the raw coal by a series of optimizations on the structure and material of the toothed roller. It has a high block rate and a small maintenance amount. With the obvious technical advantages, the promotion prospects of new-type toothed roll crusher are broad.

Chat Online

Chat Online

Send message

Send message