Rocks are naturally-occurring minerals and glass aggregates with stable appearance, bound together in a certain way. It is the material basis of the crust and upper mantle and can be divided into magmatic rock, sedimentary rock and metamorphic rock according to its genesis.

Magmatic rock, also known as igneous rock, is formed by the condensation of high-temperature molten magma on the surface or underground. Sedimentary rocks are formed by biological and volcanic action and weathering under surface conditions. They are transported, deposited and consolidated by external forces such as water, air and glacier. While metamorphic rocks are formed by metamorphism due to the change of the geological environment in which they are located.

Protean can be divided into three major categories according to the forming environment. The common and major examples of these three categories are as follows.

Major magmatic rocks: granite, andesite, diorite, rhyolite, basalt, gabbro, etc.

Major sedimentary rocks: quartz sandstone, lime conglomerate, mudstone, dolomite, gypsum, etc.

Major metamorphic rocks: gneiss, chlorite schist, phyllite, marble, mica schist, etc

No matter what kind of rock it is, the rock needs to be mechanically treated before it can be better used. Mechanical crushing is to impose a mechanical load on the rock with different properties, so that the rock can be separated from the whole.

Mechanical crushing, to a large extent, depends on the physical and mechanical properties of the rock itself, especially the main mechanical properties of the rock related to mechanical crushing. The basic rock properties that determine the difficulty of rock crushing are strength, hardness, elasticity, brittleness, etc. And the hardness of the rock is the first factor to be considered before processing.

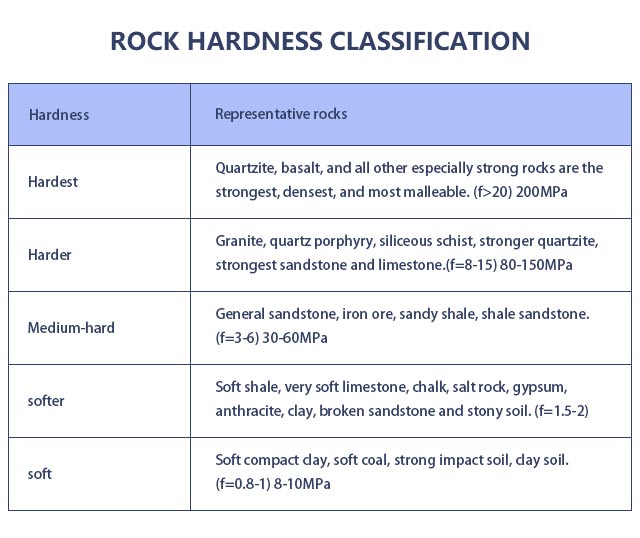

Rock hardness classification

After a long time of practice, human beings came to realize that they have difficulties in rock drilling and blowing for some rocks are not easy to destroy and break. That is, there exist some relatively strong rocks. Therefore, people use the concept of rock hardness to express the difficulty of rock crushing. Robustness is expressed by the hardness coefficient, also known as the hardness coefficient or the plat hardness coefficient (f value).

Rock hardness is also a kind of resistance to external forces, but it is a different concept compared with the strength of the rock. Strength refers to the compressive, tensile, bending, shear and other unidirectional action of the ore and rock, while the external force resisting the robustness is a comprehensive external force (such as the comprehensive force resisting shovels, picks, mechanical crushing and explosives).

Therefore, humans have found that different rocks have different hardness, so that different crushers should be used to deal with. Crusher manufacturers provide customers with different crushing solutions according to their different raw materials.

Take basalt crushing processing as an example

Basalt, a type of hard rock, belongs to the volcanic rock. Magma cools on the surface of the earth after being ejected at high temperatures and then turns into basalt. Basalt is a good material and can be made as cast stone, basalt fiber and other advanced building materials.

Basalt is used in all fields, it can be used as building decoration material because of the natural color, and it can also be produced into cast stone and well-coordinated with the surrounding environment whether it is indoors or outdoors. What's more, the alloy steel processed by basalt is hard and wearable.

In addition, it is also the material for building roads, railways and airport runways, because of its strong compression resistance, low crushing value, strong corrosion resistance and so on. Basalt materials can better bond with asphalt, which can be used to build more qualified road surface. Due to the higher hardness, wear resistance of basalt than other building materials, they are suitable for the construction of the main road with large traffic. Basalt materials are mostly neutral mineral rocks, which are more advantageous in areas with severe acid rain.

At the same time, basalt is harder than other stones such as granite, limestone, so it is more difficult to process. Ordinary basalt can be as hard as 300 Mpa, sometimes higher, and are reduced only in the presence of glass and pores. Therefore, the basalt crushing process must be designed reasonably, and the production cost should be considered as well as the investment cost of the crushing project.

Providing different crushing solutions according to the different function of basalt products

The crushed basalt products have different functions, and different crushing production schemes can be adapted according to their different functions. And because of the high hardness of basalt, it needs to be crushed with crushers of greater capacity, so the jaw crusher is often chosen for the primary crushing of basalt raw materials.

If the product is used in smelting cast stone or manufacturing fiber with small pieces of basalt, it just needs to be crushed in two stages with two crushers. The specific process is that the basalt chunks produced by blasting are delivered into the feeder, and then the feeding coarse material is sent to the jaw crusher for primary crushing, and then the belt conveyor can deliver the crushed material into secondary crushing equipment, briefly cone crusher.

In the whole process, the screening equipment is not necessary, sometimes a coarse crushing machine can complete the task alone. But, also because of the lamination principle, the particle shape of the finished products will be poor, needle flake stone content is relatively high and the internal crack is more serious, which is not willing to accept by the high-grade building, so the price is relatively low.

If finer basalt aggregate is needed, then multi-stage crushing is necessary. Generally, the mode of jaw crusher + cone crusher + impact crusher + screen is selected for processing. Jaw crusher is used for coarse crushing, cone crusher is used for medium crushing; and impact crusher for fine crushing and shaping. The impact crusher is able to produce granular stone with crushing and integral performances. Granular stone can improve the mechanical performance of the building, thus the price is high.

Of course, the cost of wear and tear of impact crusher is also higher than jaw crusher and cone crusher of the same output. It is difficult for the needle-flake stone and the original smooth stone in nature to achieve the mechanical properties formed by multi-edge cubic stone in the use of buildings. Therefore, the impact crusher is mainly used for the construction of the stone crushing plant, like roads, railways, airports, docks, and high-rise buildings.

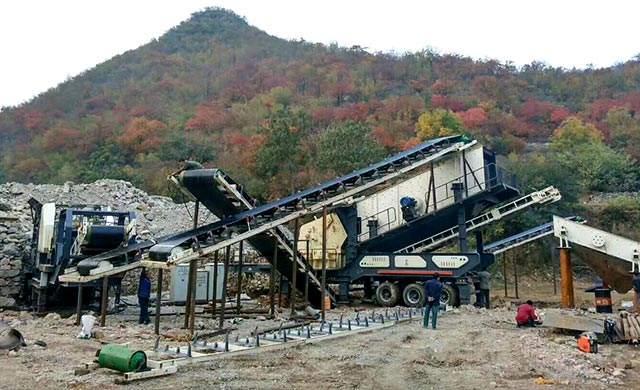

Of course, both of those two solutions are suitable for sites with flat terrain and large area. If the conditions of the production site are harsh, the terrain is steep but the customer has sufficient budget, then choosing the mobile crushing station is recommended. The integration design makes it perform in a complete way and compact combination collocation is reasonable, which requires less in the working condition.

Besides, the spare parts service life is longer, so the mobile crushing station is more suitable for operation under the bad environment with less wear and maintenance. Moreover, the mobile crushing station has lower requirements for road transportation conditions, and it is convenient and fast to transfer and enter and leave the site. The mobile crushing station covers a small area, but is equipped with a set of equipment, so it will not affect the normal production.

The production plan of any kind of material should be considered from all aspects, such as raw material hardness, output size, particle shape, customer budget, etc. And the appropriate crushing plan should be made according to different characteristics in the production of customers. Manufacturers provide multiple solutions for customers to choose according to their production requirements so everyone can get satisfied crushing solutions here.

When choosing crushing equipment, users should also make a specific analysis according to the specific problems, for example, the appropriate solution should be put forward according to the material, finished product market and geographical environment, so please trust the suggestions proposed by professional equipment manufacturers.

Chat Online

Chat Online

Send message

Send message