In the mining industry, the most common crusher types are jaw crusher and cone crusher. Jaw crusher is usually used for primary crushing, and cone crusher is used for secondary crushing.

The material of crusher plays an important role in its working efficiency and service life. However, the regular operation and maintenance are important, too.

During the using process, if the worker operates and maintains the crusher according to correct standards, it will have great significance in normal production, output, quality, service life, working efficiency and the prevention of accidents, etc.

This article will take cone crusher as an example and analyze the operation and maintenance of cone crusher.

The operation procedure of cone crusher

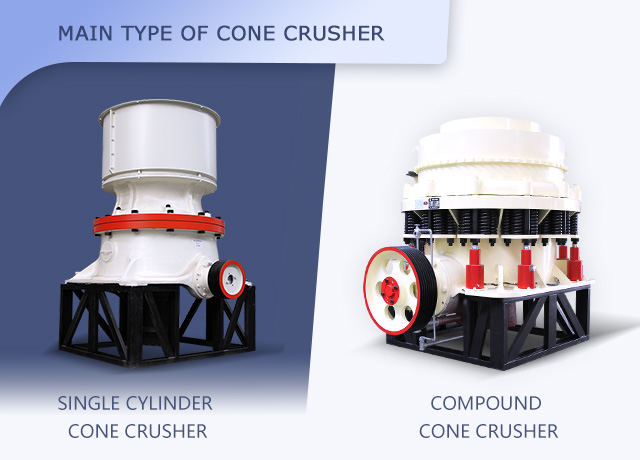

At present, the common cone crushers are mainly the single toggle cone crusher and compound cone crusher (Symons cone crusher). Although both types of cone crushers are totally different, they have the same operation procedure.

The operation procedure of cone crusher can be divided into four stages: before the start, at start-up, at run time and turning-off time. All conditions should be paid attention in each stage, and the potential problems can be found and solved timely and the service time can be prolonged.

Before the start

Check whether there are rocks or iron ore in the crushing cavity. If there are any rocks or iron ore, please clear them out before turning on the crusher.

Check whether the electrical equipment and signal instrument are working properly.

Check whether the discharging opening meets the requirements to guarantee the product size, otherwise adjust the discharging opening.

Check the quantity and temperature of oil in the fuel tank. If the temperature is lower than 20℃, the crusher cannot be turned on.

Check the oil pressure of the locking hydraulic cylinder. If the adjusting ring is locked tightly, the crusher can be turned on.

At start-up

Turn on the oil pump, and check whether the oil pressure is within the range of 0.05 to 0.12 MPa. Then check all the lubricating equipment by the oil indicator, pressure gauge and temperature gauge.

The pressure of cooling water should be 0.025 to 0.05 MPa lower than the oil to prevent lubricating oil from water.

Turn on the lubricating oil pump to run for three to five minutes. After everything runs well, turn on the crusher as required. After the crusher idles for one to two minutes, confirm that all things are well, and feed the rocks or stones.

At run-time

The feeding must be equable, and the rocks' size must meet the requirements of crushers' feeding size.

Pay attention to the operation all the time so as not to cause accidents.

Check whether the oil pump, cooler and filter work well. The scavenge oil must be lower than 60℃.

Check the drain of the water seal. If there is no water in the water seal, the crusher must stop running.

Pay attention to the sound of engine and gear, and check whether the working current of the motor is normal.

Check the wear of liner regularly, and pay particular attention to the fixed bolt on the adjusting ring which may make liner loosen.

Turning-off time

Turn off the feeding machine firstly. After discharging all the rocks in the crushing chamber, turn off the crusher, oil pump and conveyor successively.

When the temperature is lower than 0℃, the water in the water seal should be drawn off after turning off the crusher to avoid freezing.

The regular maintenance of parts

Maintenance plays an important role in the whole operation. Maintaining the crusher machine rationally can maximize the working efficiency, and here are the maintenance tips of the main parts.

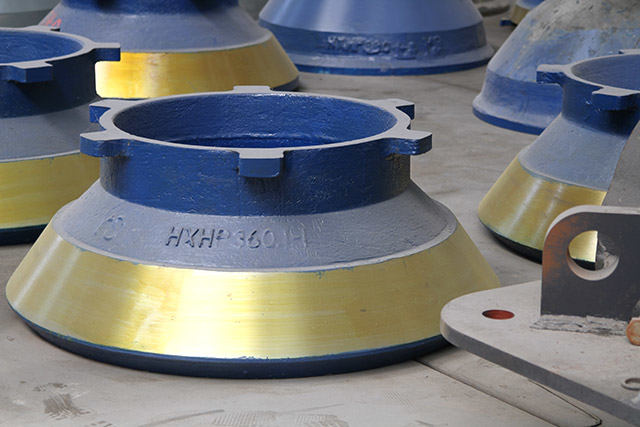

Concave

During the crushing process, there is a great impact on the concave which makes the filled zinc layer be out of shape. Therefore, the U-type bolt should be tightened frequently to make the concave fix and avoid concave from deformation.

The newly installed concave should be checked its formation and fix its bolts after two to four working days.

Mantle

The mantle is fixed by the upper bolt of the main shaft. The looseness of the bolt can make the mantle unstable, even the filled layer may fall off to cause downtime. Hence, the bolts should be often checked and fixed to avoid looseness.

Also, the newly installed concave should be checked its formation and fix its bolts after two to four working days.

Spherical bearing

The spherical bearing should be installed in the borehole of crusher closely. After a long period of working, the tightness of crusher' parts can be broken. The tightness of spherical bearing must be checked frequently, and the oil gallery of the spherical bearing should be kept clean.

Supporting sleeve

In order to prevent the sawtooth thread of supporting sleeve and adjusting ring from premature wear, the hinge pin of the main case must be fixed tightly.

Water seal for dust-proof

Water seal is the equipment for preventing crusher from dust, which is very important to the normal operation of cone crusher. Therefore, daily maintenance and checking its integrality are very necessary.

The water should be clean and free of impurities. Also, the water should be filled moderately.

Ten faults and corresponding solutions

There are ten common faults and their corresponding solutions, which will be very helpful for you.

The oil indicator shows no oil flow, but the oil pressure is lower than 0.5 MPa.

Reason: the oil temperature is too low; the switch of oil is turning off; the oil pump doesn’t work well.

Solution: heat the oil; turn on the oil switch; turn off the crusher and change the oil pump.

There is an oil pressure difference between the oil pipes of the filter.

Reason: The filter is blocked.

Solution: if the difference is more than 0.04 MPa, the filter must be cleaned well.

As the oil pressure increases, so does the oil temperature.

Reason: there is something wrong with the sleeve of the oil pipe.

Solution: check the straight sleeve and cone sleeve after turning off the crusher, and find the problem to solve it.

The scavenge oil in the fuel tank is significantly reduced.

Reason: the oil leaks from the bottom of the crusher; oil leaks from the flange plate.

Solution: turn off the crusher, check the bottom and flange plate, clean the circular groove, and add some oil to the fuel tank.

The temperature of the oil discharged from the cooler is beyond 45℃.

Reason: there is a lack of cooling water in cooler; the temperature of cooling water is higher; the cooler is blocked.

Solution: add some cooling water to cooler; check whether the hydraulic pressure is too low and try to increase it; check the temperature of cooling water.

The oil is mixed with water, which makes the amount of oil increase.

Reason: The hydraulic pressure is higher than oil pressure in the cooler.

Solution: try to make the hydraulic pressure lower than oil pressure 0.05MPa.

The concave is lifted.

Reason: the oil pressure is too low in winter; the safety valve fails to work.

Solution: preheat the oil; adjust the safety valve; change the oil pump.

The water discharged from the water seal is mixed with oil.

Reason: the circular groove in the spherical bearing is blocked.

Solution: Clean the circular groove and add oil to the fuel tank.

There is crackle when crushing stones.

Reason: the mantle or the concave of cone crusher is loose.

Solution: the bolts should be fixed frequently; check the U-type bolts of the fixed liner.

The current is too high.

Reason: there are too many rocks in the chamber; poor lubrication; the bearing or the spherical bearing is broken.

Solution: adjust the feeding; strengthen the lubrication; change the bearings.

Through the study of this article, you must have a deeper understanding of the operation and maintenance of the cone crusher. In the case of the above-mentioned failure of the crusher, the problem is analyzed and solved by referring to the method given in this article.

If the fault cannot be eliminated, welcome to consult the HXJQ Machinery, we will be happy to serve you with the fastest speed and provide you with the most effective solutions.

Chat Online

Chat Online

Send message

Send message