In recent years, as climate change brings real harm to human beings and the environment, the global awareness of environmental protection has gradually increased, and all countries have taken measures to actively cope with climate change.

Economically developed countries have decided to limit the development of environmentally polluting industries and issued a series of policies and laws to supervise the emission and pollution of factories. Even Britain, America and other developed countries have closed down their domestic mines.

In China, the environmental pollution caused by the mining industry cannot be underestimated, which has aroused the high attention of the government and residents. When one hears about mining, four questions will spring to his mind under the influence of a series of bad news related to small illegal coal mines, mining accidents, and pneumoconiosis. Will workers suffer from a series of occupational diseases in such a dusty industry? Is the natural environment bad for such a large scale of mining? Will mining bring frequent accidents? Under such concerns, all kinds of metals and non-metallic minerals are difficult to develop.

China, a big country with rich mineral resources, has a long history of mining development and plays an important role in the process of the construction of infrastructure and the development of society and economy. But as the pattern of economic development is going to gradually change from the dependence of mineral resources, the number of dried-up mines have increased dramatically and brought a series of hazards and problems to the environment, ecology, and landscape. Many abandoned mines become "scars" in the society, making the ecosystem more fragile, reducing biodiversity and causing serious ecological reverse succession.

But the mining industry, an important source of economic growth, needs to continue. This requires the government and enterprises to make joint efforts to seek scientific and environmental production and operation methods. Speaking of which, non-metallic minerals are important supporting materials for national economic and social development and high-tech industries. Non-metallic mineral industries mainly include non-metallic mineral exploration, mining, and processing, etc.

Of the many nonmetallic ores, limestone is a sedimentary rock mainly composed of the mineral calcite, accounting for about 15% of the earth's sedimentary crust. It is the basic component of the construction industry (size stone) and is the manufacturing material of aggregate, cement, lime, and the main building stone materials. Besides, it can be used in manufacturing paper, plastic, glass, paint, steel, cement, carpets, water treatment, and purification plants and various kinds of food and household products (including medicine) processing.

Current status of global limestone consumption

Limestone is a kind of precious non-renewable resource, which is widely used in human production and life. As a common building material, it has a long history of being mined. In the modern industry, limestone is the main raw material for making lime, cement and calcium carbide, and an indispensable flux in the metallurgical industry.

Limestone can also be used for the manufacture of glass, soda, caustic soda, and iron smelting with limestone as a flux.

In human life, limestone can be processed into a purer powder calcium carbonate and then applied in rubber, plastic, paper, toothpaste, cosmetics, and other fillers.

In agriculture, quicklime is used to prepare lime-sulfur mixture, Bordeaux liquor, and other pesticides. The application of hydrated lime in the soil can neutralize the acidity of the soil, improve the soil structure and supply plants with calcium.

It is interesting that brushing the trunk with lime slurry can protect the tree. Not only is limestone a significant raw material of cement and steel, but it can also be added to the low-quality fly ash to make ecology and green concrete. Therefore, it is gradually becoming a new environment-friendly raw material with a growing market.

The current demand for limestone worldwide is about 360 million tons per year, but 80 percent is for general use. High-quality lime is widely needed but their current production cannot satisfy the market due to fewer resources and low output. In recent years, countries in the Asia-pacific region have to import about 1.1 million tons of limestone from China every year due to the shortage of domestic limestone resources.

Speaking from the international market, China is superior in the limestone market because it is rich in limestone mineral resources, accounting for more than 64 percent of the world's total reserves. Due to the limited limestone minerals in most western countries, the production of cement and the exploitation of limestone mineral resources have been limited, so its dependence on China's limestone gradually increases, and the export market continues to be optimistic.

In terms of resources, some relatively large limestone mines have been basically monopolized by large cement and metallurgical enterprises, with fewer and fewer new resources. In a sense, if limestone resources are occupied, the future cement and steel market will be occupied.

Demand and price analysis of processed lime

With the transformation of the pattern of economic development and the adjustment of product structure, China's market demand for lime turns from rapid growth to stable development step by step. And it is estimated that the overall level and quality, variety will be improved during the "13th Five-Year Plan", which will cause the lime consumption to fall, and limestone for environmental protection, fine chemical, food, feed, and other industries will increase, the domestic demand is about 250 million tons. The calcium hydroxide market is estimated at 10 million tons. Among them, the demand for high-quality and highly active lime is about 100 million tons, and the demand for functional lime for calcium series products will exceed 60 million tons.

Due to the different application fields of lime products and the influence of resources, fuel, and market conditions, it varies with customers and selling places. The price ranges from 250 to 600 yuan per ton and the average price is about 400 yuan per ton. In addition, the annual sales value of the whole industry is about 100 billion yuan, but the output value of limestone and hydrated lime products is not included here.

Environmental hazards of limestone mining

Limestone products are widely used in many fields and are in great demand in the world. Therefore, many people want to seize this opportunity and invest in the limestone industry one after another. But more and more mining operations inevitably cause great damage to the environment. Among them, dust pollution, noise pollution, and soil erosion are the most serious.

Dust pollution

Most of the limestone is mined from open quarries. The air in the mining area is polluted and the dust flies. The dust produced in the process of limestone crushing and grinding is mainly limestone particles, whose main component is calcium carbonate.

The dust has an impact on the human body, plants, and soil, and the main part of the harm to the human body is particle size 10 μm dust, which is mainly harmful to the human respiratory system. The SiO2 content of limestone dust is low, and particle size 10 μm dust proportion is small, so it relatively does less harm.

The main effect on plants is that dust falls on the surface of plants and accumulates to affect direct sunlight. If dust gets wet and forms a "thin shell" on the surface of crops, it will affect the utilization of the light by plants and reduce the efficiency of photosynthesis.

The effects on soil are manifested in soil chemical elements, power of hydrogen, voids and the surrounding environment.

Noise pollution

Blasting is the biggest source of vibration in limestone mining. The seismic waves triggered by the explosion caused tremors in the surrounding area. At 200 m from the blasting center, the seismic intensity is about 5 degrees, and at 400 m, it is about 3-4 degrees.

The vibration produced by blasting is related to many factors, such as strata strike, fault, cleavage, height difference, and explosion capacity. Blasting vibration can cause damage to the buildings and structures around the blasting area.

In addition, the noise produced by crushing and grinding also has a negative impact on the people living around it. The noise of limestone mine blasting is up to 110 dB and the noise of ore crushing and grinding is about 100 dB, which does harm to human life.

The use of new environmental protection equipment has alleviated environmental damage

Now, due to the continuous update of science and technology, the equipment used for limestone mining and processing has been constantly updated, its characteristics of less pollution and environmental protection have attracted more and more attention of enterprises.

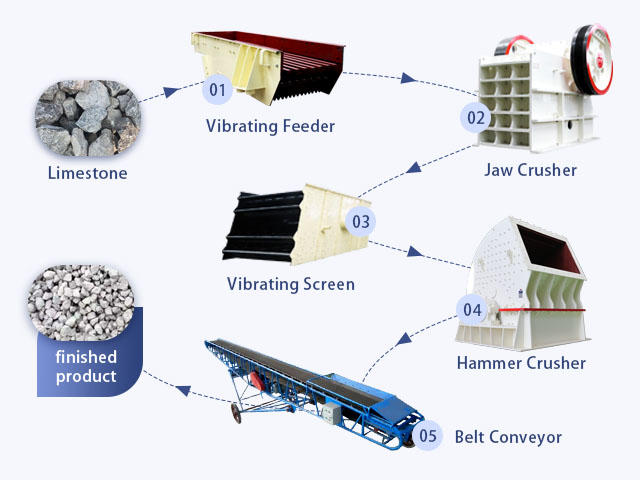

Limestone ore processing is dependent on the limestone crushing equipment, and different kinds of crushers can be chosen according to the size of the limestone ore granularity. The limestone crushing equipment, screening equipment, feeding equipment, conveying equipment shall constitute a complete set of limestone crushing production line. So how can a complete set of limestone crushing production line configure and reduce pollution?

What equipment does a complete limestone crushing line contain?

-

Crusher

According to the characteristics of limestone, jaw crusher and hammer crusher are generally selected. One or more crushers can be equipped in one crushing line.

-

Screening machine

The finished product processed by the crusher belongs to the mixture, which can be screened by the screening machine to separate the finished product of different specifications. The circular vibrating screen is a common screening machine.

-

Feeder

It is used for feeding raw limestone into the crushing chamber of the crusher. The feeder can realize automatic feeding and save labor costs.

-

Conveyor belt

It is used for conveying materials. Several conveyor belts in a limestone crushing line should be combined with working conditions and processing requirements.

Large pieces of limestone are first put into the crushing chamber of the coarse crushing machine by the feeding machine and then processed to below 100 mm by the coarsely crushing machine. The finished products are put into the screening machine for screening and then the qualified ones are put into the fine crushing machine. The limestone stones processed by the fine crushing machine have basically met the needs of the finished products.

Those that do not meet the needs are also screened out by the screening machine and sent back to the fine crushing machine for further fine crushing until qualified. The finished products are transported by the conveyor belt to the finished product storage area or warehouse.

In this process, limestone raw materials of different sizes are crushed several times to get the required size before being discharged through the discharge port, so that reducing the waste ratio.

These equipment are made of the latest materials so that quality and performance can be guaranteed. Moreover, after careful design, the dust emission of limestone crushing equipment and grinding equipment can be greatly reduced, and even new dust collectors and dust removal equipment can be equipped in the production line, which prevents the casual dust discharging from the very beginning. Environmentally friendly equipment not only reduces dust but also works with low noise, so they are widely welcomed by users.

Chat Online

Chat Online

Send message

Send message