Crushing machine is the most widely used equipment in the mining industry, and it is divided into several types according to different applications. The cone crusher is one of the most common ones and often used as the secondary crushing machine in the whole stone crushing process.

Cone crusher working site

During the operation of the cone crusher, the operator often encounters a variety of problems. This article will list the common problems of the cone crusher and our professional engineers will give the most appropriate solutions, hoping it can help you.

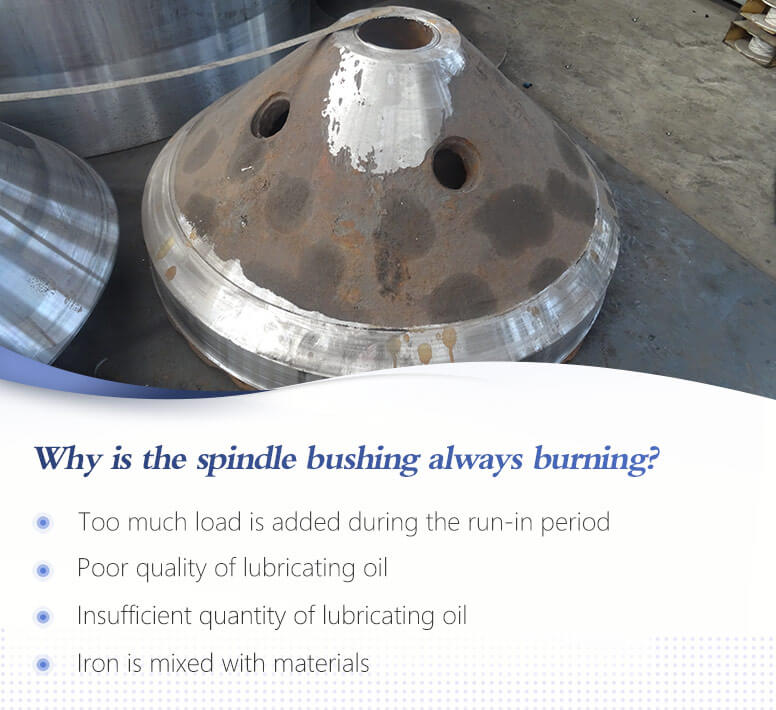

Q1: Why is the spring bushing always being burned during the operation process?

Why is the spindle bushing always burning

1. Too much load is added during the run-in period.

To ensure good contact between the new bush and the spindle, the load should be gradually added after changing the bush to avoid burning the copper bush.

2. Poor quality of lubricating oil.

Poor oil quality will reduce the viscosity of the oil film, causing the oil film to rupture in the process of breaking the spindle bushing, causing the copper sleeve to burn out. Therefore, it should be checked and replaced in time.

3. Insufficient quantity of lubricating oil.

When the oil tubing is blocked or the oil pump's capacity is reduced, it is easy to cause the copper bush to be oil-free and the oil film cannot be formed until the copper sleeve is burnt. Therefore, the pipeline and the oil pump should be inspected regularly to ensure sufficient oil.

4. Materials are mixed with iron.

If the materials are mixed with iron, iron will increase the instantaneous load of the crusher, causing the oil film to rupture and burning the copper bush. Therefore, the metal detector on the feeding machine should maintain a sensitive and reliable state.

5. The unsuitable gap between spindle bushing and spindle.

The gap between the spindle and its bushing should be kept between 1.0 and 1.2 mm. If it is too large or too small, the copper bushing will be burnt. Therefore, the gap between the spindle bushing and the spindle should be carefully checked during the replacement of new bushings.

6. The spindle is deformed.

The deformation of the spindle will cause a significant reduction in the cooperation between the spindle and the spindle bushing, especially after the crusher is running hot, causing the copper sleeve to burn. Therefore, the spindle status needs to be checked regularly.

Q2: Why does the adjustment ring vibrate abnormally?

Why does the adjusting ring vibrate abnormally

1. The threads are worn.

Generally, the gap between the locking ring and the adjusting ring of the newly installed crusher is 12.5 mm. Therefore, according to the wear condition of the adjusting ring and the locking ring thread, the gap between the two can be appropriately increased to increase the locking force.

2. The feeding size is overlarge.

Different types of cone crushers have different maximum feeding sizes. Once the size of materials exceeds the maximum feeding range, the crushing load will increase and the locking force will be relatively insufficient, causing the adjustment ring to vibrate and adversely affect the product size. Therefore, the feed size needs to be strictly controlled.

3. The feeding direction is improper.

Due to the improper or unreasonable position of the crusher feeding chamber, the feeding center and the crusher center seriously deviate, resulting in an unbalanced crushing force of the crusher, which makes the adjusting ring has a large force on one side.

The funnel design of the crusher is very important so that the feeding center should be as close as possible to the center of the crusher.

4. The locking bolt is fractured.

The locking ring and the adjusting ring are combined by four bolts. Due to there is mixed with iron in material or the feeding size is overlarge, causing the locking bolt of crusher overload and brake, and the adjusting ring vibrates. Therefore, under this condition, the locking bolts should be replaced and the gap between the locking ring and adjusting ring should be set in the correct position.

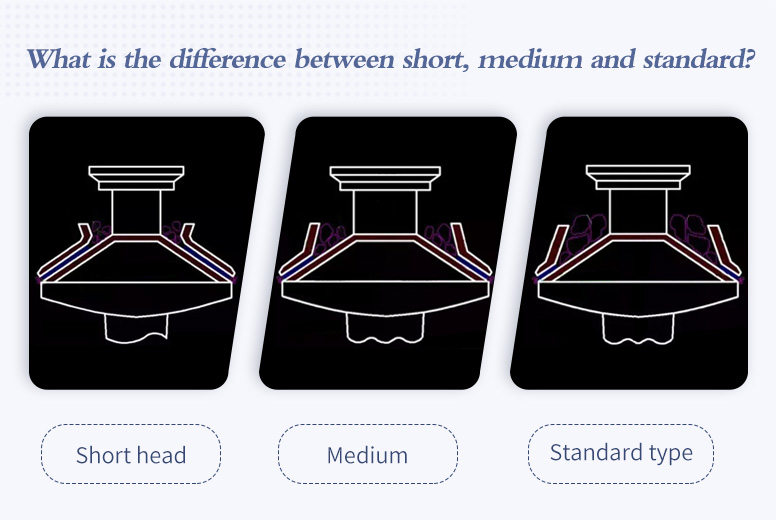

Q3: What are the differences between the short, middle and standard types of cone crushers?

The differences between short, medium and standard types of cone crusher

1. Different in the crushing cavity.

The parallel band of short type cone crusher is the longest, the medium one is the second, and the standard one is the shortest.

2. Different in the finished product size.

The short type cone crusher with the longest parallel band can crush materials to a relatively fine size. And generally, it is used in the fine crushing process; while standard type cone crusher can crush materials to a relatively coarse size, but it has a high output and usually used in the middle crushing process.

3. Different in the discharging size.

Compared with middle and short type cone crusher, the standard-type cone crusher has a wider discharging range. Therefore, the standard type cone crusher has a large capacity.

Q4: Why does the cone crusher leak oil during the crushing process?

The reason for oil leakage in cone crusher

The reasons for oil leakage in cone crusher

1. Faults of the sealing system.

During the crushing process, the worn condition of the sealing ring between the shaft frame and the mainframe should be checked. After a long term of use, this part of cone crusher may be worn and the original flexibility of the sealing ring would be reduced.

2. Blockage in return oil pipe.

The reason for the oil leakage may also be that the oil cannot be quickly discharged from the equipment, especially when the oil temperature is low. Therefore, in the production, it should be checked whether there is any dirt in the main oil drain hose or pipe. Otherwise, the accumulation of dirt will hinder the flow of oil, which will cause the cone crusher to leak oil.

3. Return hole of U-shape tile is too small.

If the oil return hole of the U-shape tile of the cone crusher is too small, the lubricating oil will be leaked, and the amount of oil returned is small, which can’t satisfy the well-lubrication of gears. In this case, it is necessary to appropriately increase the oil return hole of the U-shape tile to ensure the oil return amount, and fundamentally solve the problem of ole leakage and poor lubrication of the bevel gear.

4. Improper working pressure.

The lubricating oil enters the lower part of the main shaft from the inlet pipe and is rubbed by the lubricating friction disc. If the working pressure of the cone crusher lubrication system is improper, the oil will be ejected from the shaft gap, causing the lubricating oil to leak downward along the outer circumference of the sealing cylinder.

5. The unreasonable gap between parts.

If the gap between the inner wall of the base oil sump and the counterweight oil baffle ring plate is too small, the lubricating oil between them will easily form an oil seal under the action of tension during the working process of the cone crusher. Under the pressure of the air pressure, the oil seal will continuously overflow from the dust seal along the inner wall of the mainframe.

How to prevent cone crusher from oil leakage

How to prevent cone crusher from oil leakage

1. Ensure that the equipment is well sealed.

The design of the sealing structure is related to the effect of the sealing and the life of the sealing ring. The sealing effect of the sealing ring depends on the size of the mounting groove. The sealing ring installation groove is too deep and the compression of the sealing ring is insufficient of which will make a bad sealing effect.

Therefore, the sealing structure should be reasonably designed and processed to ensure the good sealing performance of the sealing device.

Install the sealing ring correctly to ensure that the equipment is well sealed. Do not install the sealing ring with an angled tool to prevent scratching from the rings and avoid stretching it to deformation. Lubricate the sealing ring properly for installation.

2. Regular checking.

Regularly check whether the filter is blocked or damaged, and replace the oil circuit that has been kinked to ensure the smoothness of the return line.

Check whether the gap between the inner wall of the main oil pool and the oil retaining ring on the counterweight is reasonable.

3. Prohibit the temperature rise of lubricating oil.

The increase in the temperature of the lubricating oil tends to lower the viscosity of the oil, and accelerate the sealing member aging, causing serious oil leakage.

Therefore, we should prohibit the temperature rise of the lubricating oil by increasing the heat dissipation area of the fuel tank to improve the heat dissipation effect of the fuel tank. If necessary, a cooler can be added to reduce the temperature of the lubricating oil.

The author hopes that the above questions and corresponding answers can help you. If you have any other questions about the cone crusher, please fill out the message form on the right or send us an email, our engineers will give you the first reply.

Chat Online

Chat Online

Send message

Send message